NACHI-FUJIKOSHI CORP.

Hydraulic Equipment

Main text

Energy-Saving Variable Pump Unit

NSPi series Inverter drive hydraulic unit

Energy-saving effect

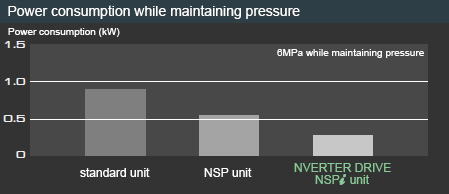

Power Consumption Reduced by Approximately 64%

(as compared to NACHI-Fujikoshi抯 standard hydraulic units while dwelling)

The base NSP unit consumes about 40% less energy than NACHI-Fujikoshi抯 standard hydraulic units. By adding the inverter drive we increase energy savings to approximately 64% as compared to NACHI-Fujikoshi抯 standard hydraulic units.

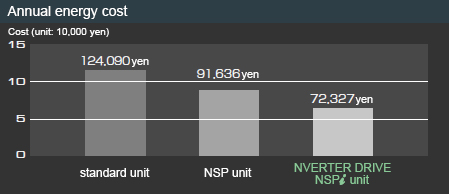

POWER RATE 40% DOWN

As compared to NACHI-Fujikoshi抯 standard hydraulic units, the NSP unit cuts 25% and the inverter drive NSPi unit cuts another approximately 40% from energy bills.

Reduces annual CO2 emissions by approximately two tons

The inverter drive NSPi unit emits about 42% less CO2 than NACHI-Fujikoshi抯 standard hydraulic units.

Equivalent to two hectares of forest

Method for calculating energy costs and CO2 emissions

| an annual operation time | 8000hour | electric power unit price | 15yen/kWh |

| maintaining pressure | 17houur/day | CO2 Emission factors | 0.555kgCO2/kWh |

| Discharge | 5hour/day | ||

*CO2 emissions factor: default value set by Ministry of Economy, Trade

and Industry & Ministry of the Environment Ordinance Number 3, 2006.

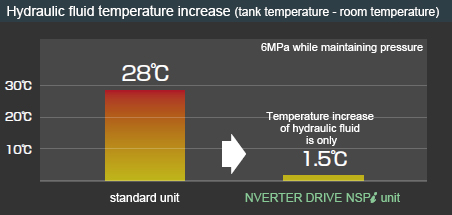

Reduce increase in hydraulic fluid temperature

1.5°C increase in ambient temperature

The NSPi series benefits your entire system by lowering oil temperature to improve machining accuracy, lengthen the life of seals and hydraulic fluid, and reduce factory air conditioning costs.

Improve machining accuracy

Lengthen life of seals and hydraulic fluid

Reduce maintenance costs

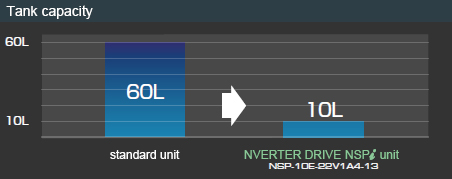

Greatly reduce the volume of hydraulic fluid

Low Nois

53db. of the wonder

The noise when dwelling is as quiet as a relaxing coffee shop.

The inverter drive saves energy and increases comfort at the same time.

(6MPa while maintaining pressure NSP-10E-22V1A4-20)